Computational Fluid Dynamics has revolutionized the field of aerodynamics, enabling engineers, designers, and researchers to analyze fluid behavior with precision and flexibility that physical wind tunnels cannot always offer. By solving complex equations that govern fluid flow, CFD provides detailed insights into airflow behavior around objects such as aircraft, vehicles, turbines, and even buildings.

This article explores the advanced principles of CFD aerodynamics, delves into its computational foundations, and examines its critical applications across various industries. Whether you’re a seasoned engineer or a student entering the field, understanding how CFD aerodynamics works is crucial for modern design and optimization challenges.

What Is CFD in Aerodynamics?

CFD (Computational Fluid Dynamics) refers to the use of numerical methods and algorithms to solve and analyze problems that involve fluid flows—air, water, or gases—by computing values such as velocity, pressure, density, and temperature in a given space.

In aerodynamics, CFD is primarily used to analyze airflow over and around solid bodies, such as:

- Aircraft wings and fuselage

- Automobile shapes

- Wind turbine blades

- Skyscrapers and bridges

CFD simulates these interactions digitally, using computational models, rather than relying entirely on wind tunnel tests or physical prototypes.

The Physics Behind it

CFD is based on the Navier-Stokes equations, which describe the motion of viscous fluid substances. These equations include:

- Continuity equation (mass conservation)

- Momentum equations (Newton’s second law applied to fluid motion)

- Energy equations (conservation of energy in thermodynamic systems)

However, these equations are nonlinear partial differential equations that rarely have analytical solutions. CFD uses discretization techniques such as:

- Finite Volume Method (FVM)

- Finite Element Method (FEM)

- Finite Difference Method (FDM)

to convert them into solvable algebraic equations.

Key Components

To understand how CFD is applied in aerodynamic problems, we must break it into its core components:

1. Geometry and Meshing

- The shape (geometry) of the object is defined in 3D space.

- The space around the object is divided into small elements or cells (mesh or grid).

- Mesh density greatly affects accuracy; finer mesh near surfaces (boundary layer regions) captures shear and pressure gradients more accurately.

2. Boundary Conditions

- Essential for defining how the fluid enters and exits the simulation domain.

- Includes:

- Inlet velocity or pressure

- Outlet pressure or static conditions

- Wall (no-slip) boundaries

- Symmetry or periodic boundaries (for repetitive geometries)

3. Solver and Turbulence Modeling

- The CFD solver calculates flow variables using numerical methods.

- Turbulence modeling is vital, as most aerodynamic flows are turbulent.

- RANS (Reynolds-Averaged Navier-Stokes): Suitable for steady-state problems.

- LES (Large Eddy Simulation): Resolves larger turbulent structures.

- DNS (Direct Numerical Simulation): Most accurate, but computationally expensive.

4. Post-Processing

- Visualization of results: streamlines, pressure contours, velocity vectors, vortex structures, etc.

- Performance parameters: drag coefficient, lift coefficient, pressure distribution, flow separation zones.

Advanced Principles in CFD Aerodynamics

While basic simulations help in visualizing flow, advanced involves several sophisticated techniques:

1. Boundary Layer Analysis

- CFD accurately models the boundary layer, the thin region near a surface where viscous effects dominate.

- Essential in predicting flow separation, skin friction drag, and stall conditions on wings.

2. Flow Transition Modeling

- Important for simulating laminar-to-turbulent transition, especially in low Reynolds number flows like UAVs and gliders.

3. Compressible vs. Incompressible Flows

- CFD can simulate compressible flows (high-speed aerodynamics) with shocks, expansions, and Mach number effects.

- Common in aerospace applications like supersonic aircraft and rocket nozzles.

4. Aeroelasticity and Fluid-Structure Interaction (FSI)

- CFD is often coupled with structural analysis tools to model aeroelastic behavior, such as wing flutter or deformation under load.

- FSI simulations are critical in aircraft, wind turbines, and even biomedical applications.

5. Optimization and Machine Learning

- Advanced CFD tools integrate design optimization algorithms (genetic algorithms, adjoint solvers).

- Emerging integration of AI/ML models helps predict flow behavior and reduce simulation time using data-driven techniques.

Industry Applications

The versatility of CFD has made it indispensable across multiple sectors. Let’s explore some major applications:

1. Aerospace and Aviation

Perhaps the most obvious application, CFD is used extensively in the design and analysis of:

- Aircraft wings and fuselage: CFD helps reduce drag and increase lift-to-drag ratios.

- Jet engines and inlets: Ensuring efficient airflow and combustion.

- Control surfaces and flight stability: Tail and rudder performance, stall characteristics.

- Unmanned Aerial Vehicles (UAVs): CFD helps refine compact aerodynamic profiles and assess wind gust tolerance.

Modern aircraft manufacturers like Boeing and Airbus conduct thousands of CFD simulations before ever building a prototype.

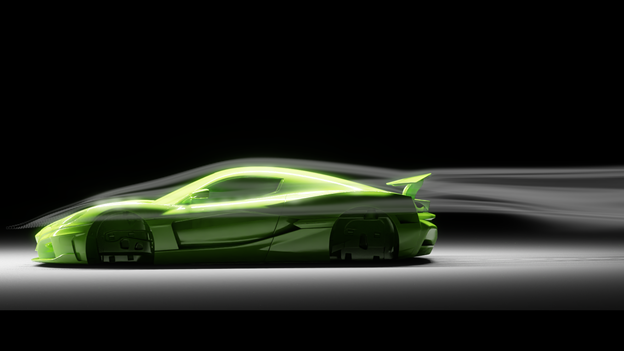

2. Automotive Industry

CFD is transforming how cars are designed for both performance and efficiency:

- Drag reduction: Lower drag improves fuel economy and high-speed stability.

- Cooling systems: Simulating radiator airflow, brake cooling, and under-hood ventilation.

- Aeroacoustics: Minimizing wind noise in cabins.

- Downforce generation: Especially critical in motorsports (Formula 1, NASCAR), where airflow over wings and diffusers directly impacts speed.

3. Wind Energy and Renewable Power

Wind turbine performance is directly linked to aerodynamic efficiency:

- CFD is used to design blades, optimize pitch, and predict power output.

- It also helps simulate wake effects between turbines in a wind farm, affecting layout decisions.

- CFD simulations of atmospheric boundary layers inform site assessments and turbine placement.

4. Architecture and Civil Engineering

Modern buildings must consider wind loads, air circulation, and pollutant dispersion:

- CFD helps simulate urban airflow, heat island effects, and smoke behavior in emergencies.

- Architects use it to optimize natural ventilation, especially in sustainable or “green” buildings.

- Bridges, stadiums, and high-rise towers undergo wind CFD testing for safety and comfort.

5. Sports and Human Performance

Even sports teams and athletes benefit from:

- Designing aerodynamic cycling helmets, swimsuits, or rowing shells.

- Optimizing ski suits or Formula 1 driver positioning for reduced drag.

- Modeling airflow around racecourses or indoor sports arenas for comfort and performance.

6. Marine and Naval Engineering

While primarily a fluid dynamics application, CFD is used to simulate air-water interactions:

- Air resistance on ship superstructures

- Spray formation and ventilation on high-speed vessels

- Submarine hull drag and underwater vehicle propulsion

Challenges and Limitations

Despite its advantages, CFD comes with challenges:

- High computational cost, especially for 3D, transient, or LES/DNS simulations.

- Accuracy depends on mesh quality, boundary conditions, and model fidelity.

- Validation with physical experiments is still crucial to ensure credibility.

- CFD requires skilled interpretation—misreading results can lead to design errors.

Nonetheless, continual improvements in computing power, cloud-based solvers, and machine learning are rapidly overcoming these barriers.

Conclusion

CFD has evolved from a supplementary tool to a critical component of design and analysis in nearly every sector involving fluid flow. As CFD software becomes more powerful and user-friendly, even small businesses and academic institutions can perform simulations that were once the domain of large labs.

The future of CFD aerodynamics lies in:

- Real-time simulation

- AI-assisted design

- Cloud-based computation

- Integration with augmented reality for immersive post-processing

By understanding the advanced principles and embracing its applications, engineers and designers can unlock new frontiers in efficiency, sustainability, and innovation. Whether it’s optimizing an aircraft wing or designing the next electric car, CFD remains at the heart of aerodynamic progress.